How to regain control and optimize supplier strategies

Imagine a procurement process as a maze of scattered purchases, where every department acts in isolation. One team buys from a supplier not contracted by the organization, another from a local store, while the finance department struggles to track where every dollar goes.This is the reality of transactional procurement, a landscape of hidden costs, compliance risks and operational chaos. In this fragmented world, your purchasing looks like this:

- Employees choose vendors based on momentary convenience

- No centralized visibility into spending

- Multiple vendors for similar products

- Compliance becomes an afterthought

- Cost savings are measured in pennies, not strategic value

The consequences? Silent profit erosion. Uncontrolled spending. Potential regulatory risks. And an administrative burden that suffocates your team’s potential.

But what if procurement could be a strategic tool, not an administrative headache?

Let’s explore how to transform your procurement from a reactive, fragmented process to a proactive, value-driven strategy. We’ll reveal how enterprises are regaining control, eliminating hidden costs and turning procurement into a competitive advantage.

Why standardized suppliers matter

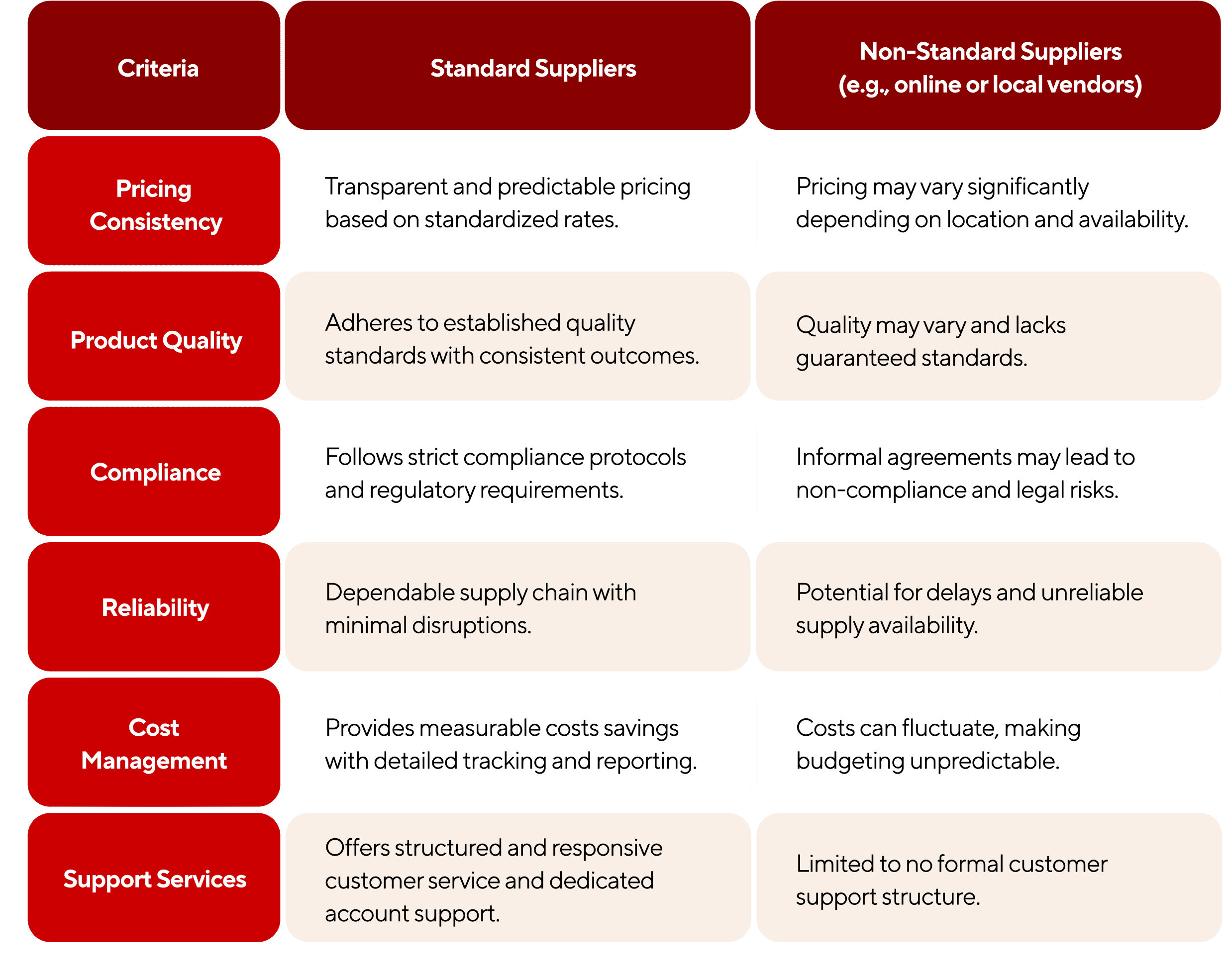

The difference between standardized and non-standardized suppliers is much more significant than convenience. Allowing your employees to purchase from non-standard suppliers, whether intentionally or not, can have real, inconvenient consequences, such as higher overall costs, compliance risks and potential quality issues.

For example, imagine your organization needs to source supplies for all your office breakrooms located in multiple locations across the country.

With a standard supplier:

You typically get negotiated bulk pricing, and that can translate into significant cost savings. Transparent contracts with clear compliance guidelines are also the norm. You can usually take advantage of detailed reporting tools to track spending patterns and adjust your procurement strategy effectively.

With non-standard local vendors (including well-known online vendors):

You may face variable pricing based on location or availability, and that can lead to unpredictable expenses. Non-standard suppliers often rely on informal agreements that lack the compliance protocols of standard suppliers. This could expose you to risks like inconsistent product quality or supply chain delays.

By choosing a data-driven approach with a standard supplier, you gain measurable cost savings, improved reliability and stronger legal compliance — key elements for your organization’s success.

Standard suppliers versus non-standard suppliers

Regaining control over procurement

To regain control and optimize supplier strategies, you need to focus on centralization, policy enforcement and technological integration.

Consolidate Vendors

Reducing the number of suppliers simplifies your procurement process. This centralization improves spend visibility and boosts negotiation leverage. When selecting vendors, prioritize those who offer a wide range of quality products at competitive prices and can either provide technology/reporting or seamlessly integrate with your chosen third-party tools.

A real-world example:

“Consolidating our supplier base from over 100 to just 20 trusted vendors transformed our business operations. We experienced reduced procurement costs, faster order processing and improved product consistency. Strategic partnerships allowed us to negotiate better terms, secure volume discounts and benefit from quicker delivery times. It’s been a game changer!”

— Staples Business™ Enterprise Customer (Retail Industry)

Strengthen Policy Enforcement

Getting employees to stick to procurement policies takes consistent effort, especially with high staff turnover after COVID. Clear, regular communication is essential to highlight the benefits of staying compliant and the risks of making off-policy purchases. For organizations without automated approvals or real-time tracking, it’s even more important to keep the messaging consistent across all levels to ensure everyone stays on track.

A real-world example:

A leading tech firm implemented an automated system for purchase approvals and trained their teams on procurement policies. As a result, they decreased rogue spending and ensured that purchases aligned with the company’s strategic goals.

Leverage technology for real-time data

Use procurement software with automated reporting, spend analytics and vendor rating tools. AI and predictive analytics can spot inefficiencies and support data-driven decisions.

A real-world example:

A global manufacturing company adopted an AI-driven procurement platform that allowed them to analyze spend patterns in real time. This technology integration helped them reduce waste, optimize inventory levels and make more informed procurement decisions.